- Data Sheet: D2-29

{ content: "Catalogo Generale"; font-size: 16px; font-weight: bold; color: #000; display: inline-block; vertical-align: middle; margin-bottom: 40px; background-color: var(--category-color); padding-left: 10px; color: #fff; text-transform: uppercase; padding-top: 8px; padding-bottom: 8px; margin-bottom: 0px; display: block; margin-bottom: 20px; width: 100%; } .rl_tabs.top > ul.nav-tabs > li.active a { height: unset; text-transform: unset; background-color: var(--category-color) !important; color: #fff !Important; padding-top: 4px !important; padding-right: 10px !important; }/*SUB-MENU*/ .tm-bottom-b .title_yellow, #tm-main-bottom .title_yellow, #downloadarea .title_yellow, .tm-sidebar-a .uk-panel-title, .rl_tabs.top > ul.nav-tabs > li a, .product_page .uk-width-medium-3-10 .section_title, .caratteristiche_prodotto td, .caratteristiche_prodotto strong { font-size: 16px !Important; text-transform: uppercase; } .tm-sidebar-a .uk-panel-box .uk-nav-side > li > a, #tm-main-bottom .uk-width-large-1-6 div a, .tm-bottom-b .uk-width-large-1-6 div a, .caratteristiche_prodotto td, .field-entry .field-value, .tm-sidebar-a .uk-nav-sub li a { color: #424242 !Important; font-size: 16px !Important; font-weight: 500 !Important; } .tm-sidebar-a .uk-panel-box .uk-nav-side > li.uk-active > a { color: #fff !Important; } .tm-bottom-b .title_yellow, #tm-main-bottom .title_yellow, #downloadarea .title_yellow { width: calc(100% - 10px); font-size: 15px !Important; margin-top: 0; padding-left: 9px; vertical-align: top; line-height: 16px; padding: 9px; } .title_yellow { background-color: var(--category-color); display: inline-block !Important; width: auto; color: #fff !Important; padding: 6px; font-size: 18px; padding-left: 20px; padding-right: 20px; margin-bottom: 29px !Important; font-weight: 700; } .fields-container:before { content: ""; background: url(/images/diflon/icona-download-difline-sv.jpg); max-width: 32px !Important; width: 32px !Important; background-size: 32px; display: inline-block; height: 32px; background-repeat: no-repeat; vertical-align: middle; } .field-entry a { font-size: 12px; padding-left: 8px; font-weight: bold; text-decoration: none; color: #000; display: block; margin-top: -10px; } .fields-container.gen:before { content: ""; background: url(/images/diflon/icona-download-pdf-sv-cut.jpg); max-width: 32px !Important; width: 32px !Important; background-size: 32px; display: inline-block; height: 32px; background-repeat: no-repeat; vertical-align: middle; } .field-entry { display: inline-block !Important; position: relative; margin-bottom: 0px; vertical-align: middle !Important; background-color: unset !Important; } .field-value { color: #000 !Important; border-top: 0px !Important; padding: 0px !Important; vertical-align: middle !Important; padding-left: 8px !Important; } #downloadarea .title_yellow { margin-top: 20px; margin-bottom: 20px !Important; } .btn-primary { display: none !Important; } .rl_tabs > ul.nav-tabs > li:before { content: ' ' !important; background-image: url('/images/diflon/freccia-blu.jpg') !Important; color: var(--category-color); margin: 0; padding: 0; display: table-cell; background-color: #fff; height: 32px; width: 32px; text-align: center; font-size: 14px; margin-right: 10px; vertical-align: middle; padding-top: 3px; background-size: contain; background-repeat: no-repeat; position: relative !Important; display: table-cell !Important; padding: 0px !Important; background-color: unset !Important; vertical-align: middle !Important; } .rl_tabs.top > ul.nav-tabs > li a { background-color: #fff; position: relative; display: table-cell !Important; padding: 0px !Important; padding-left: 12px !Important; text-transform: unset !Important; } .rl_tabs.top > ul.nav-tabs > li a.rl_tabs-toggle.nn_tabs-toggle.nav-link { padding-left: 12px !Important; } .rl_tabs.top > ul.nav-tabs > li.active a { background-color: #fff; color: #424242; } .rl_tabs.top > ul.nav-tabs > li a { color: #424242 !Important; font-weight: 500 !Important; padding-left: 10px !Important; } .rl_tabs.top > ul.nav-tabs > li.active a, .rl_tabs.top > ul.nav-tabs > li.active a:hover, .rl_tabs.top > ul.nav-tabs > li a:hover { background-color: #fff !Important; color: #424242 !Important; } .rl_tabs.top > ul.nav-tabs > li.active a { height: unset !Important; text-transform: unset; background-color: var(--category-color) !important; color: #fff !Important; padding-top: 4px !important; padding-right: 10px !important; width: 90% !Important; } #tm-bottom-b ul.nav-tabs { width: 23% !Important; } .tm-bottom-b .rl_tabs-tab a { height: unset; text-transform: unset; background-color: rgb(244, 244, 244) !important; padding-top: 4px !important; padding-right: 10px !important; width: 90% !Important; } #set-rl_tabs-1:before { content: "Charateristics"; font-size: 16px; font-weight: bold; color: #000; display: inline-block; vertical-align: middle; margin-bottom: 40px; background-color: var(--category-color); margin-left: 10px; padding-left: 10px; color: #fff; text-transform: uppercase; padding-top: 8px; padding-bottom: 8px; margin-bottom: 0px; display: block; margin-bottom: 20px; width: 82%; text-align: left; padding-top: 22px; padding-bottom: 22px; margin-top: 9px; }/*END SUB-MENUC*//* RESPONSIVE */ @media screen and (max-width: 769px) { #tm-main .tm-middle { display: flex; } #tm-main .tm-main { order: 1; } #tm-main .tm-sidebar-a { order: 2; } .rl_tabs.align_justify > ul.nav-tabs > li { width: 100% !Important; display: block; margin-bottom: 5px !Important; height: unset !Important; min-width: unset !Important; } .rl_tabs.align_justify > ul.nav-tabs > li a { overflow: hidden; white-space: nowrap; display: block; text-overflow: ellipsis; max-width: 300px; } .tm-bottom-a .uk-grid + .uk-grid.misure_container { margin-top: -25px !Important; } .uk-slideshow > li > img { opacity: 1 !Important; visibility: visible; padding: 12px; } .product_page .uk-slideshow li { min-height: unset !Important; height: unset !Important; } .techspectitl { margin-left: 25px !Important; } #tm-bottom-b ul.nav-tabs, #set-rl_tabs-1:before, .rl_tabs.outline_content > .tab-content { width: 100% !Important; } .diflon_category:before { margin-left: 24px !Important; } }/* END RESPONSIVE *//*DIMENSIONI PAG*/ .cceqblg:before { content: "Utilities"; font-size: 16px; font-weight: bold; color: #000; display: inline-block; vertical-align: middle; margin-bottom: 40px; background-color: var(--category-color); /* margin-left: 40px; */ padding-left: 10px; color: #fff; text-transform: uppercase; padding-top: 4px; padding-bottom: 4px; margin-bottom: 0px; display: block; margin-bottom: 15px; margin-top: 20px; width: 100%; } aside .title_yellow { margin-top: 15px !Important; } @media (min-width: 768px) { .uk-width-medium-1-4 { width: 21% !Important; } } @media (min-width: 768px) { .uk-width-medium-3-4 { width: 76% !Important; margin-left: 3% !Important; } } .rl_tabs.align_justify > ul.nav-tabs > li:last-child { width: 100% !Important; } .rl_tabs.align_justify > ul.nav-tabs > li:last-child a { width: calc(100% - 58px); } .cceqblg div:before { content: ' ' !important; background-image: url('/images/diflon/freccia-blu.jpg') !Important; color: var(--category-color); margin: 0; padding: 0; display: table-cell; background-color: #fff; height: 32px; width: 32px; text-align: center; font-size: 14px; margin-right: 10px; vertical-align: middle; padding-top: 3px; background-size: contain; background-repeat: no-repeat; } .cceqblg a { display: table-cell; vertical-align: middle; line-height: 22px !important; padding-left: 10px !Important; padding-top: 0px; text-decoration: none !Important; color: #424242 !Important; font-size: 16px !Important; font-weight: 500 !Important; }/*END DIM PAG*/

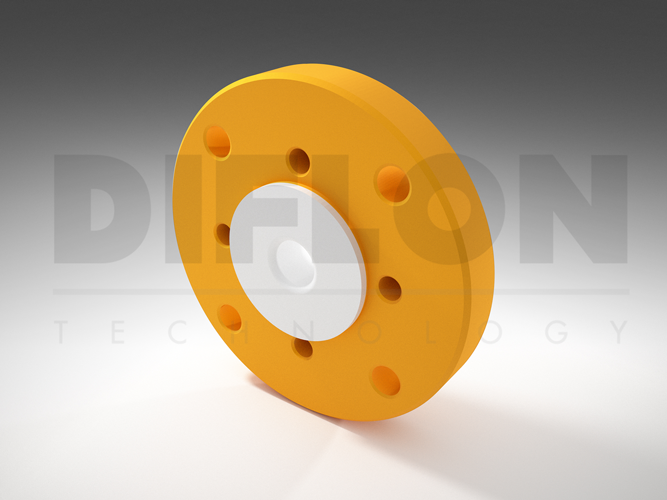

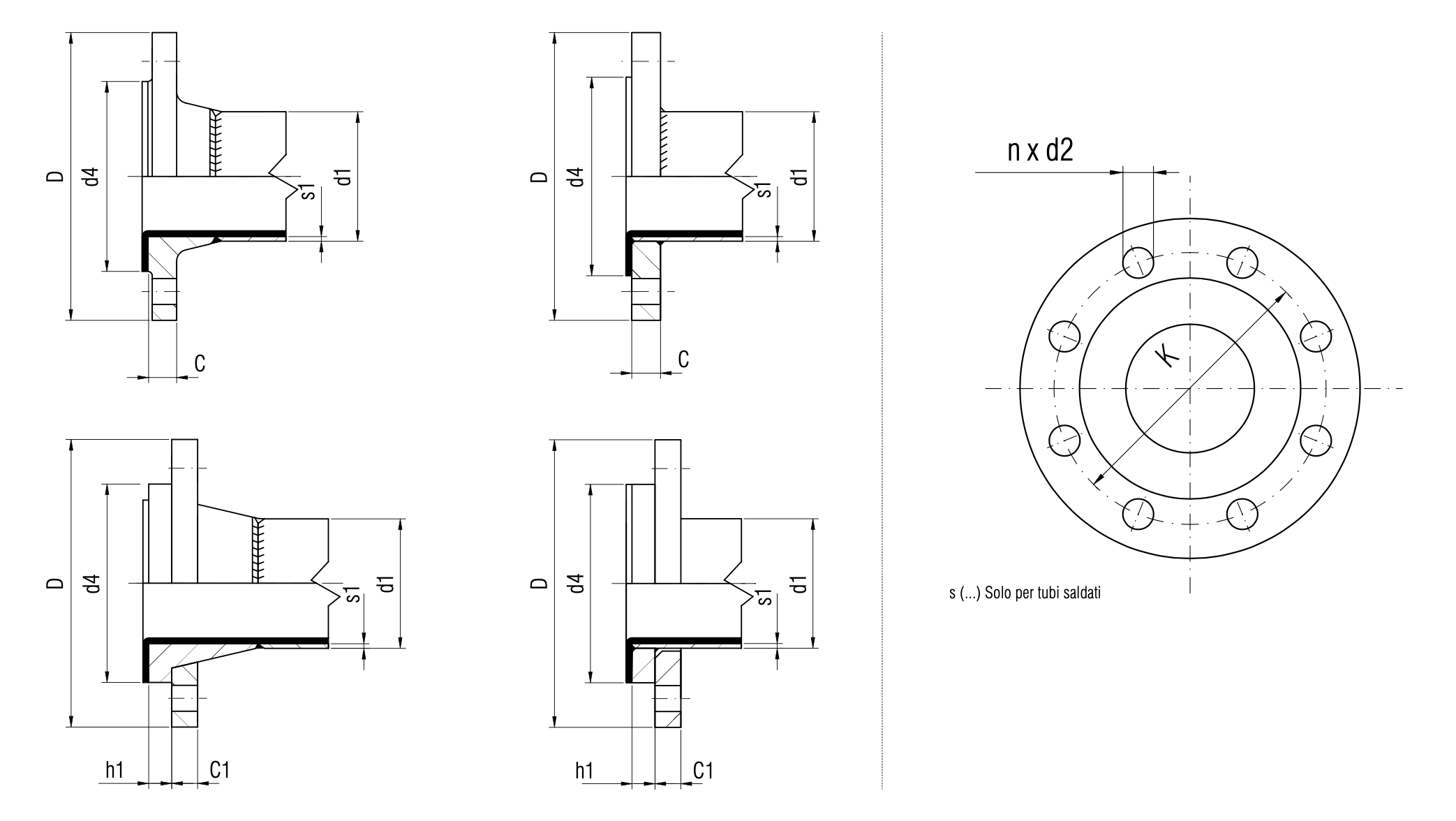

| DN | D | K | d4 | n | d2 | C | C1 | h1 | d1 x s1 | Bolt |

|---|---|---|---|---|---|---|---|---|---|---|

| 15 | 95 | 65 | 45 | 4 | 14 | 16 | 14 | 10 | 26,9 x 2,3 | M 12 |

| 20 | 105 | 75 | 58 | 4 | 14 | 18 | 16 | 12 | 26,9 x 2,3 | M 12 |

| 25 | 115 | 85 | 68 | 4 | 14 | 18 | 16 | 12 | 33,7 x 2,6 | M 12 |

| 32 | 140 | 100 | 78 | 4 | 18 | 18 | 18 | 12 | 42,4 x 2,6 | M 16 |

| 40 | 150 | 110 | 88 | 4 | 18 | 18 | 18 | 12 | 48,3 x 2,6 | M 16 |

| 50 | 165 | 125 | 102 | 4 | 18 | 18 | 20 | 14 | 60,3 x 2,9 | M 16 |

| 65 | 185 | 145 | 122 | 4 | 18 | 18 | 20 | 14 | 76 x 2,9 | M 16 |

| 80 | 200 | 160 | 138 | 8 | 18 | 20 | 20 | 16 | 88,9 x 3,2 | M 16 |

| 100 | 220 | 180 | 158 | 8 | 18 | 20 | 22 | 16 | 114,3 x 3,6 | M 16 |

| 125 | 250 | 210 | 188 | 8 | 18 | 22 | 22 | 18 | 139,7 x 4,0 | M 16 |

| 150 | 285 | 240 | 212 | 8 | 22 | 22 | 24 | 18 | 168,3 x 4,5 | M 20 |

| 200 | 340 | 295 | 268 | 8 | 22 | 24 | 24 | 20 | 219,1 x 5,9 | M 20 |

| 250 | 395 | 350 | 320 | 12 | 22 | 26 | 26 | 22 | 273,0 x 6,3 | M 20 |

| 300 | 445 | 400 | 378 | 12 | 22 | 26 | 26 | 22 | 323,9 x 7,1 | M 20 |

| 350 | 505 | 460 | 438 | 16 | 22 | 26 | 30 | 22 | 355,6 x 8,0 | M 20 |

| 400 | 565 | 515 | 490 | 16 | 25 | 26 | 32 | 24 | 406,4 x 8,0 | M 24 |

| 450 | 615 | 565 | 550 | 20 | 25 | 26 | 36 | 24 | 457,2 x 8,0 | M 24 |

| 500 | 670 | 620 | 610 | 20 | 25 | 28 | 38 | 26 | 508,0 x 9,5 | M 24 |

| 600 | 780 | 725 | 725 | 20 | 30 | 28 | 42 | 26 | 610,0 x 9,5 | M 27 |